CROSS REFERENCE - Sprocket Sets

| JP | ROLLMASTER | JP | ROLLMASTER |

| JP5601 | CS6100 | JP5633T | CS1197 |

| JP5602 | CS6120 | JP5634T | CS10000 |

| JP5603 | CS6110 | JP5635T | CS10010 |

| JP5605 | CS3040 | JP5636T | CS10015 |

| JP5606T | CS5140 | JP5978 | CS3080 |

| JP5611 | CS4040 | JP5979 | CS6000 |

| JP5612 | CS7010 | JP5980 | CS3170 |

| JP5613 | CS5300 | JP5981 | CS1000 |

| JP5614 | CS7050 | JP5981T | CS1040 |

| JP5615T | CS1136 | JP5982 | CS3010 |

| JP5618T | CS1135 | JP5983 | CS5310 |

| JP5619 | CS6141 | JP5984 | CS7000 |

| JP5620 | CS6150 | JP5985 | CS5000 |

| JP5621T | CS2090 | JP5989 | CS5100 |

| JP5622T | CS1180 | JP5990 | CS4000 |

| JP5623T | CS1185 | JP5991 | CS2000 |

| JP5625 | CS3255 | JP5991T | CS2020 |

| JP5627T | CS1190 | JP5992 | CS5320 |

| JP5628T | CS1195 | JP5994 | GD6000 |

| JP5629 | CS7100 | ||

| CS1116 | |||

| JP5632T | CS1198 |

INDUCTION HARDENING

JP Engineering induction hardens all crank sprockets for all chain sets, crank gears for

full steel timing gear sets and oil pump drive gears.

Induction hardening is used to improve tooth life of your gears and sprockets, as well

as pre-work harden gears and sprockets before they are installed onto engines.

WHAT IS INDUCTION HARDENING?

Induction hardening is a process where steel is hardened by means of induction

heating and a subsequent quenching of water.

WHY INDUCTION HARDEN?

The advantages of induction hardening gear and sprocket teeth include:

- 1. To localise hardening of tooth surfaces where the hardness is needed. Unlike

- 2. Hardened teeth are pre-work hardened. The process of induction hardening

- 3. The speed of hardening is a rapid process. It takes approximately 30 seconds

- 4. The use of computers makes it easy to control the depth of hardness

HOW DOES IT WORK?

The part to be hardened is placed inside an “Applicator” coil, through which an alternating current is then passed.

This coil is round as we use it for gears and sprockets and is usually made of copper tubing which has water passing through it to prevent overheating.

Multiple pieces are placed onto the rod which rotates, heating the parts and then feeding the rod downward into the quench water.

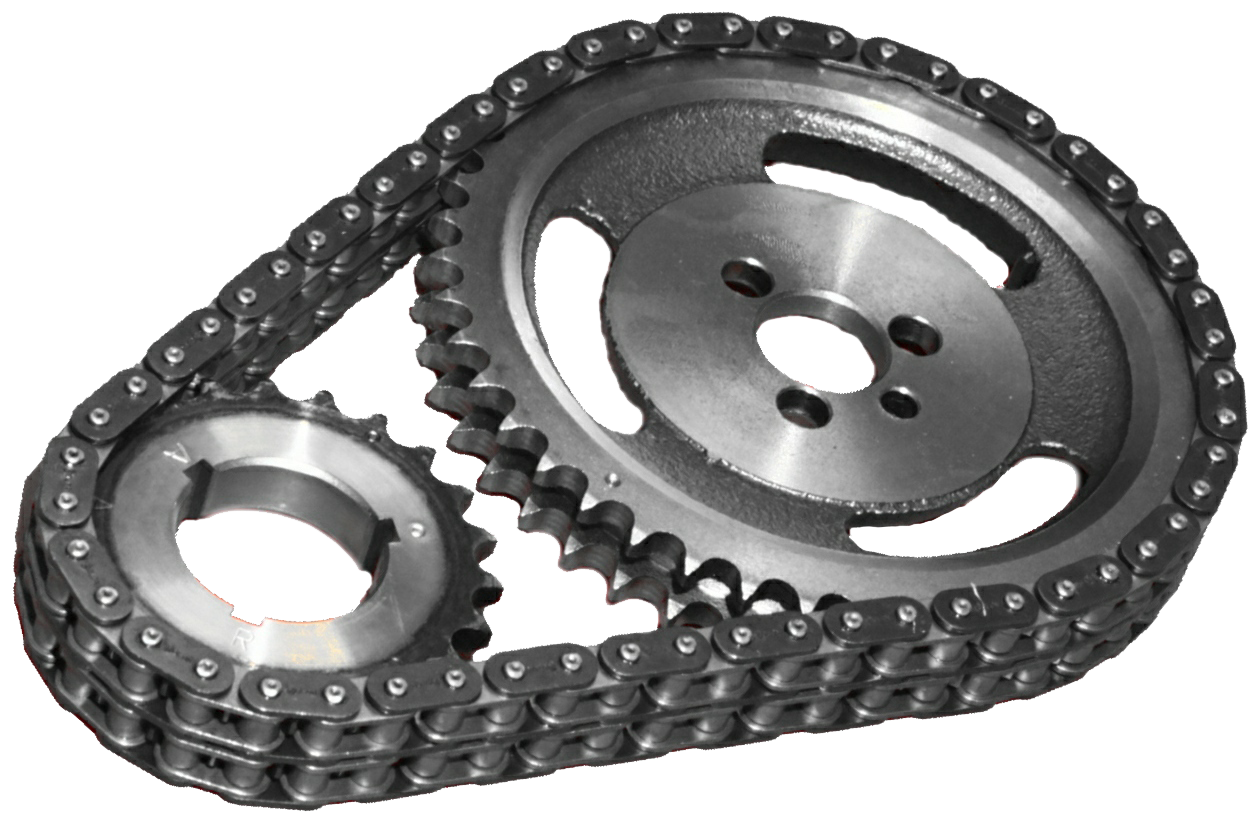

DR Evenfire

Timing Chain Sets – Performance by Design |

|||

AMC/Rambler |

|||

| JP5629 | 6cyl181-252ci | DR | 7 Keyways |

BMC |

|||

| JP5607 | B Series | DR | Leyland Engine - MGB |

Buick |

|||

| JP5612 | V6 196-252ci | DR | Evenfire |

| JP5984 | V6 198-231ci | DR | Oddfire |

| JP5601 | V6 231ci | SR | N, C, & L VIN No up to 1991 |

| JP5603 | V6 231ci | SR | L VIN No 1992 onwards |

| JP5619 | V6 231ci | SR | L36 & L67 Inc Supercharged |

| JP5620 | V6 231ci | DR | L36 & L67 Inc Supercharged |

| JP5984 | V8 215-350cI | DR | |

Chevrolet |

|||

| JP5619 | V6 231ci | SR | Impala Vin K |

| JP5620 | V6 231ci | DR | Impala Vin K |

| JP5610T | V8 409ci | DR | Impala w/Torrington Bearing |

| JP5981 | V8 262-400ci | DR | Small Block |

| JP5981T | V8 262-400ci | DR | Small Block - w/ Torrington Bearing |

| JP5630T | V8 262-400ci | DR | Small Block - w/ Torrington Bearing, suit Big Block Snout1.6”, Chain 60P |

| JP5616T | V8 | DR | Small Block - w/ Torrington Bearing, suit Raised Cam, Rocket Block |

| JP5615T | V8 Gen III | DR | LS1 & LS6 - w/ Torrington Bearing |

| JP5618T | V8 Gen III | SR | LS1 & LS6 - w/ Torrington Bearing |

| JP5622T | V8 Gen III | SR | LS2 - w/ Torrington Bearing - w/one Trigger Sensor |

| JP5623T | V8 Gen III | DR | LS2 - w/ Torrington Bearing - w/one Trigger Sensor |

| JP5634T | V8 Gen III | DR | LS2 – w/ Torr Brg – One Trigg Sensor –RHS Block with Cam Raised .388” |

| JP5635T | V8 Gen III | SR | LS7 – w/ Torr Brg – 3 Bolt Early – Multi Trigg Sensors – Long Oil Pump Drive |

| JP5636T | V8 Gen III | DR | LS7 – w/ Torr Brg – 3Blt Early – Multi Trigg – RHS Block, Cam Raised .388” |

| JP5627T | V8 Gen III | SR | LS7 - w/ Torrington Bearing - 3 Bolt Early Series –Multi Trigger Sensors |

| JP5628T | V8 Gen III | DR | LS7 - w/ Torrington Bearing - 3 Bolt Early Series –Multi Trigger Sensors |

| JP5991 | V8 396-454ci | DR | Big Block - w/ Torrington Bearing |

| JP5991T | V8 396-454ci | DR | Big Block |

| JP5621T | V8 | DR | LS6 - w/Torrington Bearing |

| JP5633T | V8 Gen III | SR | L98 – w/Torrington Bearing - Single Bolt – Multi Trigger Sensors |

| JP5632T | V8 Gen III | DR | L98 – w/Torrington Bearing - Single Bolt – Multi Trigger Sensors |

Chrysler/Jeep |

|||

| JP5613 | Slant 6 225ci | DR | L6 |

| JP5983 | 215-245-265 | DR | Hemi 6 – 3 Bolt Cam Sprocket |

| JP5992 | 215-245-265 | DR | Hemi 6 – Single Bolt Cam Sprocket |

| JP5985 | V8 273-292ci | DR | Small Block |

| JP5989 | V8 361-440ci | DR | Big Block - Single Bolt |

| JP5606T | V8 361-440ci | DR | Big Block - Three Bolt |

| JP5629 | 6cyl 4.0-4.2ltr | DR | Jeep |

Ford |

|||

| JP5608 | 6cyl 200ci | DR | Canadian Block |

| JP5625 | 6cyl | DR | EA-AU Vernier Cam Gear only |

| JP5978 | V8 302-351ci | DR | Cleveland |

| JP5980 | 6cyl 200-250ci | DR | 3.3-4.1ltr |

| JP5982 | V8 302-351ci | DR | Windsor Pre EFI |

| JP5605 | V8 302-351ci | DR | Windsor EFI |

| JP5611 | V8 352-428ci | DR | FE Big Block including Cobras Jet |

| JP5990 | V6 429-460ci | DR Big Block | |

Holden |

|||

| JP5601 | V6 | SR | VN |

| JP5602 | V6 | DR | VN |

| JP5603 | V6 | SR | VP-VN, to VIN #VH1426330, 7 Keyway |

| JP5619 | V6 | SR | VR-VS-VT – from eng #1426331, not for Supercharger |

| JP5620 | V6 | DR | VR-VS-VT – from eng #1426331, not for Supercharger |

| JP5615T | V8 Gen III | DR | LS1 & LS6 - w/ Torrington Bearing |

| JP5618T | V8 Gen III | SR | LS1 & LS6 - w/ Torrington Bearing |

| JP5622T | V8 Gen III | SR | LS2 - w/ Torrington Bearing - w/one Trigger Sensor |

| JP5623T | V8 Gen III | DR | LS2 - w/ Torrington Bearing - w/one Trigger Sensor |

| JP5634T | V8 Gen III | DR | LS2 – w/ Torr Brg – One Trigg Sensor –RHS Block with Cam Raised .388” |

| JP5635T | V8 Gen III | SR | LS7 – w/ Torr Brg – 3 Bolt Early – Multi Trigg Sensors – Long Oil Pump Drive |

| JP5636T | V8 Gen III | SR | LS7 - w/ Torrington Bearing - 3 Bolt Early Series –Multi Trigger Sensors |

| JP5628T | V8 Gen III | DR | LS7 - w/ Torrington Bearing - 3 Bolt Early Series –Multi Trigger Sensors |

| JP5621T | V8 | DR | LS6 - w/Torrington Bearing |

| JP5633T | V8 Gen III | SR | L98 – w/Torrington Bearing - Single Bolt – Multi Trigger Sensors |

| JP5632T | V8 Gen III | DR | L98 – w/Torrington Bearing - Single Bolt – Multi Trigger Sensors |

| JP5979 | V8 | DR | 253-308ci |

Mercruiser |

|||

| JP5626T | V8 496ci | DR | Big Block HO Marine 8.1ltr |

Oldsmobile |

|||

| JP5612 | V6 196-252ci | ||

Pontiac |

|||

| JP5612 | V6 181-252ci | DR | Evenfire |

| JP5984 | V6 198-231ci | DR | Oddfire |

| JP5601 | V6 231ci | SR | C VIN to 1991 |

| JP5603 | V6 231ci | SR | L VIN from 1992 |

| JP5618T | V8 Gen 111 | SR | LSI & LS6 w/Torrington Bearing |

| JP5619 | V6 231ci | SR | L36 & L37 Inc Supercharged |

| JP5620 | V6 231ci | DR | L36 & L37 Inc Supercharged |

| JP5614 | V8 287-455ci | DR | Big Block |

| JP5615T | V8 Gen 111 | DR LS2 & LS6 | w/Torrington Bearing |

Rover |

|||

| JP5984 | V8 3500 | DR | Range Rover |

Timing Chain Sets – Cast Iron |

|||

Chevrolet |

|||

| JP5975 | V8 283-400ci | Small Block | Cast iron Cam sprocket |

| Ford | |||

| JP5972 | V8 302-351ci | Cleveland | Cast Iron Cam sprocket |

| JP5974 | 6cyl 250ci | Falcon EFI | Cast Iron Cam sprocket |

| JP5974T | 6cyl 250ci | Falcon EFI | Cast iron Cam sprocket |

| JP5977 | V8 289-351ci | Windsor | Cast Iron Cam sprocket |

Holden |

|||

| JP5971 | V8 253-304-308ci | Cast Iron Cam sprocket | |

Timing Chain Sets – Cast Iron

The JP Engineering range of replacement cast iron timing chain sets are ideal for the budget minded.

Each set contains a cast iron cam sprocket, induction hardened multiple keyway steel crank sprocket and true roller chain.

All sprockets are CNC machined.

Gear Drives – Performance by Design |

|||

Chevrolet |

|||

| JP5702 | V8 265-400ci | Small block | |

| JP5706 | V8 396-454ci | Big block | |

Ford |

|||

| JP5703 | V8 302-351ci | Cleveland | |

| JP5704 | V8 302-351ci | Windsor | Non EFI |

| JP5708 | V8 302-351ci | Windsor | EFI |

| JP5705 | V8 429-460ci | Big Block | |

Holden |

|||

| JP5701 | V8 253-304-308ci | ||

Gear Sets – Performance by Design |

|||

Holden |

|||

| JP5986 | 6cyl | FX-EK | |

| JP5954 | 6cyl | EH-HZ, VB-VK METRIC pitch | |

| JP5994 | 6cyl | EH-HZ, VB-VK STRAIGHT cut | |

| JP5999 | 6cyl | EH-HZ, VB-VK HE&ZLICAL cut | |

Gear Drive Information

- ‘A’ grade Drawn Cup Needle Roller Bearings rated at 12000rpm and dynamic

- load rating of 8.6kN (1935lbf)

- Thrust washers rated to 16000rpm and dynamic load capacity of 7.2kN

- (1620lbf)

- Hardened Gears for longer life under harsh conditions.

- CNC turned for greatest accuracy.

- Precision cut idler plates.

- Glass beaded gears to relieve stress.

- Case hardened and ground idler shafts to improve bearing life.

- Cam Bushes in 0°, 2°, 4°, and 6° for greater timing flexibility.

- Chevy Kits include Cam Lock Tab, Thrust Bearing Assembly and Cam Button Assembly

- Detailed instructions for correct installation.

Oil Pumps – Performance by Design |

|||

Holden |

|||

| JP9451 | 6cyl | EH-HZ, VB-VK | Standard Volume |

| JP9456 6cyl | EH-HZ, VB-VK | High Volume | |

| JP9471 | V8 253-304-308ci | VN, VL, VP | Standard Volume |

| JP9491 | V8 253-304-308ci | VN, VL, VP | High Volume |

Ford |

|||

| JP9436 | 6cyl | XY-XF, ZD-ZG, TC-TF | High Volume |

| JP9438 | 6cyl | XY-XF, ZD-ZG, TC-TF | Standard Volume |

| JP9437 | 6cyl | DA-DF, EA-EL, NA, NF | High Volume |

| JP9439 | 6cyl | DA-DF, EA-EL, NA, NF | Standard Volume |

| JP9440 | 6cyl | AU Series 1, 11 & 111 Standard Volume | |

Oil Pump Information

JP Performance Oil Pumps are manufactured to the highest quality.

Manufactured from cast iron on CNC equipment, every pump is bench tested before packing to ensure they are working correctly and to guarantee quality and longevity.

Just ask racers... they rely on these oil pumps to keep their engines running.

Myths about High Volume Oil Pumps

High volume oil pumps are best used when an engine reaches higher RPM. This is usually above 4500RPM.

At this point the ability of a standard oil pump to adequately feed the connecting rod bearing is strained.

A high volume oil pump will solve oil starvation problems above this rev range.

What high volume oil pumps will not do is:

- 1. It will not replace a rebuild, in a worn-out engine.

- 2.It will not pump the oil pan dry. Both solid and hydraulic lifters have metering valves to limit flow of oil to the top of the engine. If a pan is pumped dry, it is because the holes that drain back the oil are congested.

- 3. It will not wear out distributor gears. The load on the gear is directly related to the resistance to flow. Distributor gear failures are usually caused by a worn out gear on a new cam gear, incorrect gear angles and/or worn bearings causing misalignment.

- 4.It will not cause foaming of the oil. With any oil pump, the excess oil not needed by the engine is recirculated within the pump. Any additional foaming is usually created by revving the engine higher. The oil thrown from the rod bearings is going faster and causes the foaming. This is why high performance engines use a Windage tray.